This product requires a service every 12 months to ensure it continues to operate safely and efficiently. Regular servicing helps maintain performance, prevent issues, and extend the lifespan of your equipment.

Service Interval Reminder

This product requires a service every 12 months to ensure it continues to operate safely and efficiently. Regular servicing helps maintain performance, prevent issues, and extend the lifespan of your equipment.

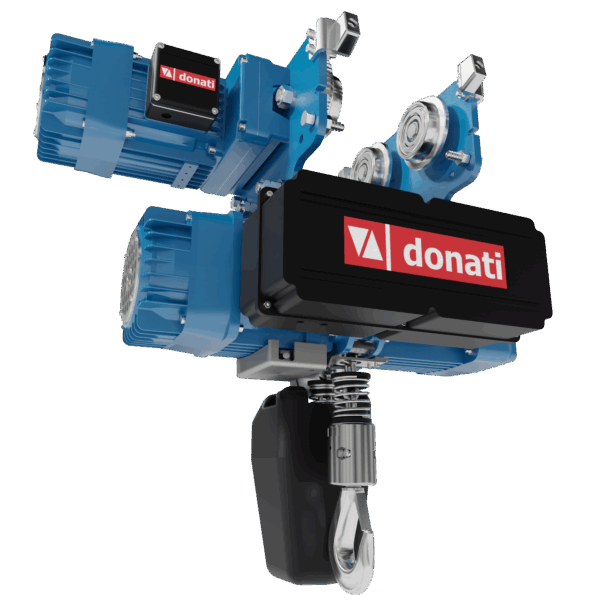

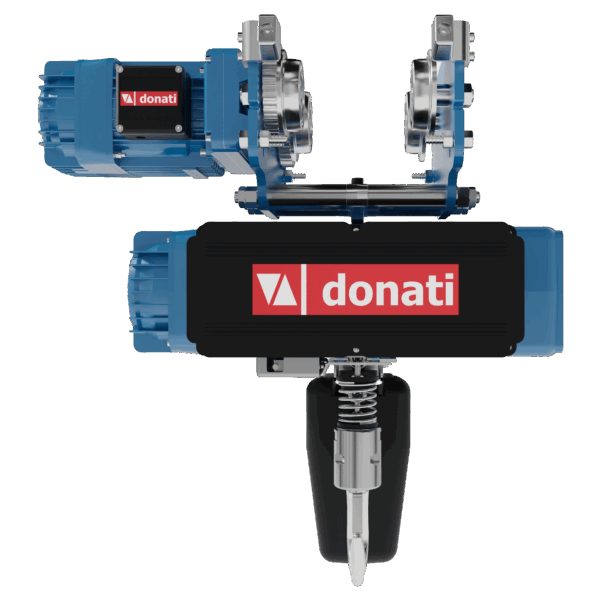

Donati DMK Series Electric Chain Hoist with Powered Trolley – Up to 4,000 kg, Single or Dual Speed Travel, IP55 Protection

DON-ECHDMK-PT

The Donati DMK Powered Trolley Electric Chain Hoist offers precise vertical lifting and powered horizontal travel for loads up to 4,000 kg. Available with single or dual travel speeds, it combines self-braking conical motor technology, IP55-rated protection, and robust construction to deliver efficient, low-maintenance performance for industrial lifting operations.

From: £3,175.70£3,810.84 Exc VATInc VAT

Description

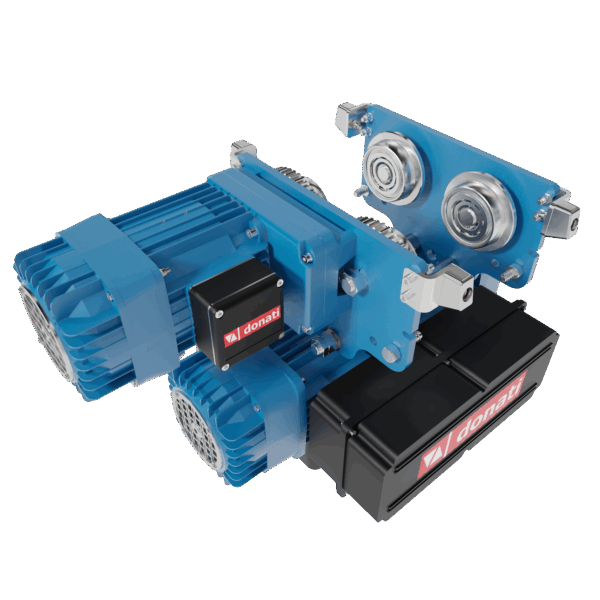

The Donati DMK Series Electric Chain Hoist with Powered Trolley delivers precision lifting and smooth powered horizontal travel for industrial and commercial applications. Combining the proven reliability of the DMK hoist mechanism with a robust motor-driven trolley, this system offers both single-speed and dual-speed travel options, ensuring safe and accurate load positioning along the beam.

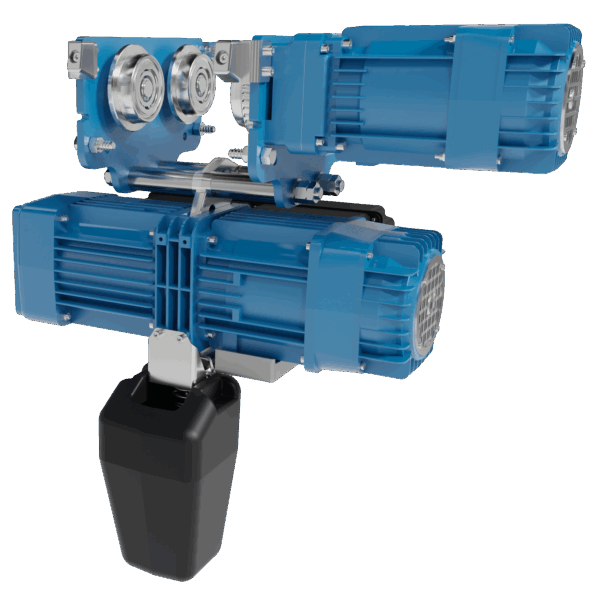

Built to meet the demands of modern lifting environments, the DMK hoist features a self-braking conical motor, precision-machined gearing, and high-quality alloy components for exceptional durability and safety. The electrostatically-applied, water-repellent paint finish provides outstanding resistance to corrosion and wear, maintaining performance even in challenging conditions.

The Donati DMK range consists of four basic sizes (DMK 1–4), covering capacities from 100 kg to 4,000 kg, and conforms to FEM/ISO service classifications 1Bm (M3), 1Am (M4), and 2m (M5).

Available with single or dual lifting speeds and 1-fall or 2-fall chain configurations, these hoists support a standard hook path of up to 12 m, with extended heights available upon request.

Electrical Protection and Components:

Lifting and travel motors: IP55, insulation class “F”

Brake: IP23

Limit switch: IP65

Power cables: IEC 20/22 II, 450/750 V insulation

Power Supply Options:

Three-phase 400 V, 50 Hz (standard)

Single-phase 230 V, 50 Hz (for DMK 1–3 up to 800 kg, single-speed)

Non-standard voltages and frequencies available on request

Operating Conditions:

Temperature range: –10 °C to +40 °C

Max. relative humidity: 80 %

Max. altitude: 1,000 m above sea level

Indoor installation, well-ventilated, non-corrosive environments

Noise level: <85 dB(A) under full load

Technical information

| WLL | 1 tonne, 1.6 tonne, 2 tonne, 2.5 tonne, 3.2 tonne, 4 tonne, 125kg, 250kg, 500kg |

|---|---|

| Lifting Speed (m/min) | 2.5/0.8, 3.2, 3.2/1, 4, 4/1.2, 6.3, 6.3/2.1, 8, 8/2.5, 16 |

| Beam Width | 58-220mm, 74-220mm |

| Trolley Speed | 11, 22, 7/22 |

Key Features

Load Capacity: 100 – 4,000 kg

Configuration: Electric chain hoist with powered trolley

Travel Speeds: Single or dual (motor-driven horizontal travel)

Motor: Self-braking conical motor for reliable lifting performance

Lifting Speed: Single or dual (depending on model)

Chain Falls: 1 or 2 (depending on capacity)

Hook Path: Standard up to 12 m (custom lengths available)

Protection Ratings: IP55 motors / IP23 brake / IP65 limit switches

Power Supply: 400 V three-phase / 230 V single-phase (selected models)

Temperature Range: –10 °C to +40 °C

Noise Level: <85 dB(A) at full load

Finish: Water-repellent electrostatic paint for corrosion resistance

Compliance: FEM/ISO 1Bm – 2m service classification

Applications: Manufacturing lines, warehouses, workshops, maintenance bays, and light-to-heavy industrial operations