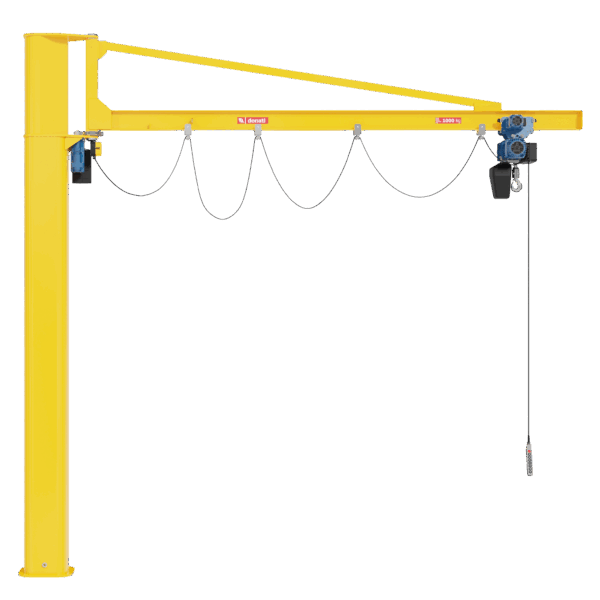

Donati Powered Slewing Column Jib Crane – Series CBE H-Version Overbraced, 280° Rotation

DON-PSCMJCH-OBCBE

The Donati CBE H-Version Overbraced Slewing Jib Crane is a robust, electrically powered rotating crane designed for medium-to-heavy duty load handling where space restrictions, obstacles, or high manoeuvring frequency make manual rotation impractical. Featuring 280° powered slewing, a rigid overbraced arm, and Donati’s proven motorised rotation system, this crane delivers precise, smooth and reliable lifting performance across industrial, marine, logistics and manufacturing environments.

Price on request

Description

The Donati CBE Series – H-Version Overbraced Jib Crane is engineered for applications where manual rotation is not feasible due to frequent handling cycles, heavy or awkward loads, or the presence of fixed obstacles within the working area. This high-performance model offers electrically powered slewing up to 280°, delivering controlled, low-effort handling for operators while maintaining Donati’s exceptional standards of durability and safety.

The H-Version is constructed using a laminated double T-beam jib supported by one or two high-strength staybolts, providing increased lifting capacity and outreach compared to the cantilever T-Version. Suitable for loads 250 kg to 2,000 kg with jib lengths 4 m to 8 m, this model is ideal for workshops, warehouses, fabrication plants, marine yards, loading docks, storage depots, and assembly areas.

A precision-engineered rotating arm pivots on a system of rolling bearings for smooth movement. The rotation mechanism consists of a vertical motor reducer with sealed epicyclic gears running in an oil bath and a self-braking conical motor. The drive sprocket engages with the arm’s toothed crown for positive, controlled slewing. Progressive acceleration and braking are achieved through a frequency inverter, supplied in 230 V single phase or three-phase for cranes outside the 400 V range.

The integrated electrical supply system includes dual control panels (or optional single panel), low-voltage circuits for operator safety, multipolar festooned cables, and a shockproof pendant control. Optional independent sliding pendants, acoustic alarms and extended electrical interfaces can also be installed.

This series offers excellent reliability, easy installation, and high long-term performance, representing the Donati standard of industrial lifting technology.

Technical information

| WLL | 250kg, 500kg, 1,000kg, 1,600kg, 2,000kg |

|---|---|

| Mounting Substrate | Cast Foundation, Concrete Slab |

Key Features

Donati electrically powered slewing – 280° rotation

Overbraced H-Version arm for maximum strength and reach

Standard capacities 250–2,000 kg

Jib lengths 4 m, 5 m, 6 m, 7 m, 8 m

Laminated double T-beam jib with staybolts

Rolling-bearing mounted rotation system

Epicyclic motor-reducer with self-braking motor

Frequency inverter for smooth, controlled slewing

Low-voltage (48 V) control circuits for operator safety

Festooned multipolar cable system for hoist/trolley

Shockproof pendant control with optional quick-connect plug

Optional independent sliding pendant along jib

Electrical rotation limit switches supplied as standard

Acoustic alarm option

Main isolator switch with padlock facility

Designed for use in areas with restricted access and fixed obstacles