This product requires a service every 12 months to ensure it continues to operate safely and efficiently. Regular servicing helps maintain performance, prevent issues, and extend the lifespan of your equipment.

Service Interval Reminder

This product requires a service every 12 months to ensure it continues to operate safely and efficiently. Regular servicing helps maintain performance, prevent issues, and extend the lifespan of your equipment.

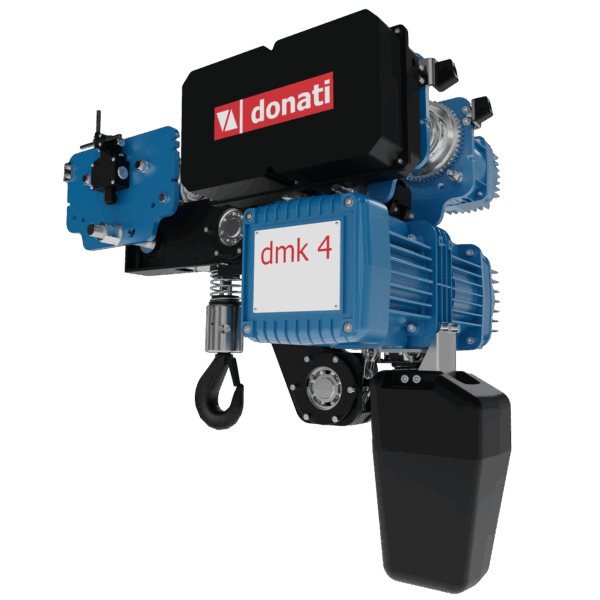

Donati DMK Series Low Headroom Electric Chain Hoist – Up to 4,000 kg, Chain Return System, IP55 Protection

DON-ECHDMK-LH

The Donati DMK Low Headroom Electric Chain Hoist provides maximum hook travel in confined spaces thanks to its integrated chain return system. Designed for loads up to 4,000 kg, it combines the proven reliability of the DMK hoist with a compact, efficient, low-profile trolley system, making it the ideal solution for limited headroom lifting applications.

Price on request

Description

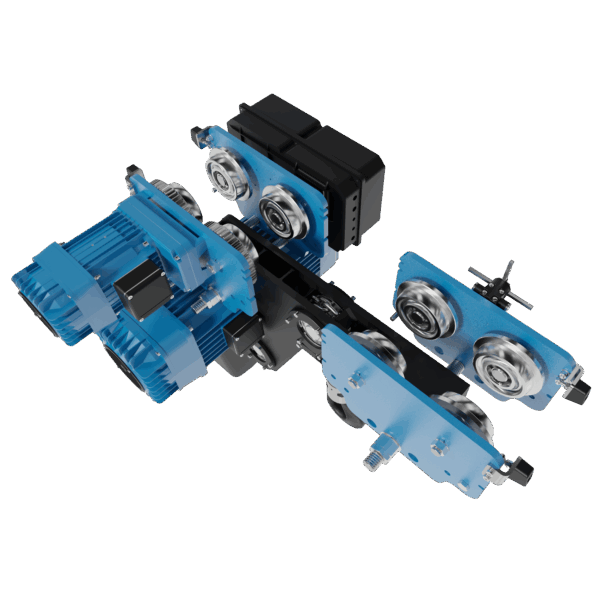

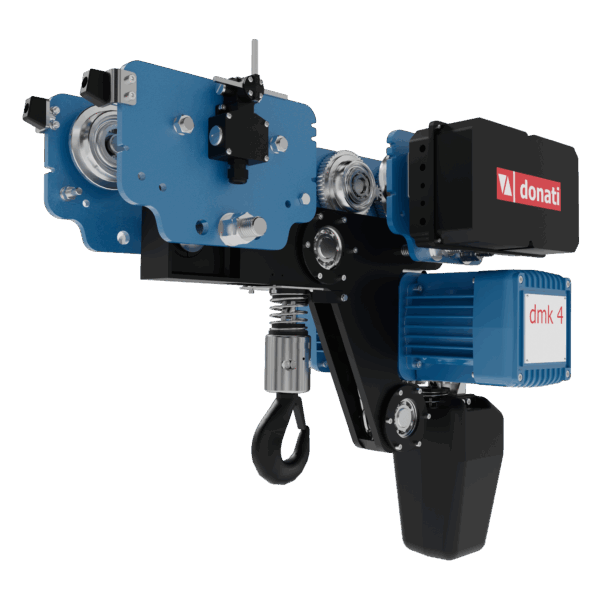

The Donati DMK Series Low Headroom Electric Chain Hoist is purpose-designed for lifting applications where space constraints and maximum hook height are critical. Featuring a compact chain return system mounted directly on the trolley, this variant allows operators to achieve the maximum possible lifting height while maintaining smooth, precise movement along the beam.

Built with Grade 8 alloy steel components and the proven DMK self-braking conical motor, this low headroom model combines strength, safety, and superior design efficiency. The trolley-mounted chain return system minimizes headroom loss, making it ideal for facilities with restricted lifting spaces such as workshops, maintenance areas, and industrial production lines.

All Donati DMK chain hoists are designed to meet international FEM/ISO standards, providing long-term reliability, high safety margins, and low maintenance costs. The electrostatically applied, water-repellent paint finish ensures durability even in harsh environments.

The DMK range includes four base models (Donati DMK 1–4), supporting capacities from 100 kg to 4,000 kg, with service classifications 1Bm (M3), 1Am (M4), and 2m (M5).

Available in single or dual lifting speeds, 1-fall or 2-fall chain configurations, and standard lifting heights up to 12 m (longer lifts available on request).

Electrical and Protection Ratings:

Lifting and travel motors: IP55, insulation class “F”

Brake: IP23

Limit switch: IP65

Power cables: IEC 20/22 II, 450/750 V insulation

Electrical Supply Options:

Three-phase 400 V / 50 Hz (standard)

Single-phase 230 V / 50 Hz (for DMK 1–3 up to 800 kg, one speed)

Optional voltages and frequencies available on request

Operating Conditions:

Temperature range: –10°C to +40°C

Maximum relative humidity: 80%

Installation altitude: up to 1,000 m above sea level

Indoor use in well-ventilated, non-corrosive environments

Noise level: <85 dB(A) at full load

Technical information

| WLL | 1 tonne, 1.6 tonne, 2 tonne, 2.5 tonne, 3.2 tonne, 4 tonne, 125kg, 250kg, 500kg |

|---|---|

| Lifting Speed (m/min) | 2.5/0.8, 3.2, 3.2/1, 4, 4/1.2, 6.3, 6.3/2.1, 8, 8/2.5, 16 |

| Beam Width | 58-220mm, 74-220mm |

Key Features

Load Capacity: 100 – 4,000 kg

Design: Low headroom with trolley-mounted chain return system

Purpose: Maximum hook height in restricted headroom spaces

Motor: Self-braking conical motor for precision lifting

Lifting Speeds: Single or dual, depending on chain hoist model

Chain Falls: 1 or 2 (depending on load)

Hook Path: Standard up to 12 m (custom on request)

Protection Ratings: IP55 motor / IP23 brake / IP65 limit switches

Power Supply: 400 V three-phase (230 V single-phase for select models)

Temperature Range: –10°C to +40°C

Noise Level: <85 dB(A)

Finish: Water-repellent electrostatic coating for corrosion protection

Compliance: FEM/ISO 1Bm–2m classifications

Applications: Low-clearance lifting, factory maintenance, workshops, and compact production areas