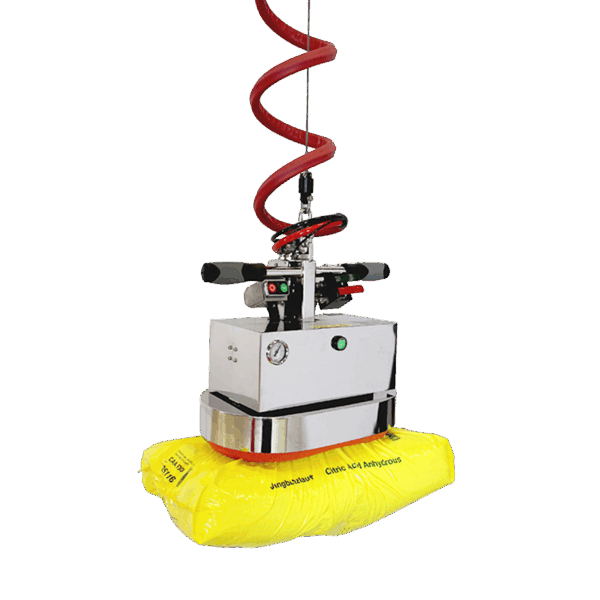

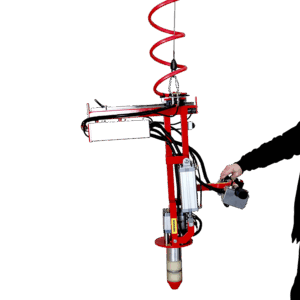

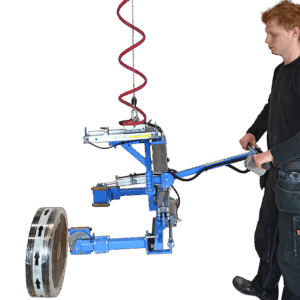

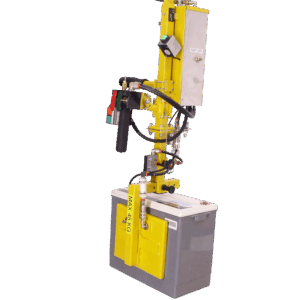

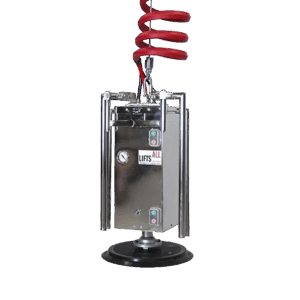

Lifts All Vacuum Sack Gripper – Lifting Tool for Paper & Plastic Sacks | Models 92-10006 / 92-10020

LTA-VSG-9210006/20

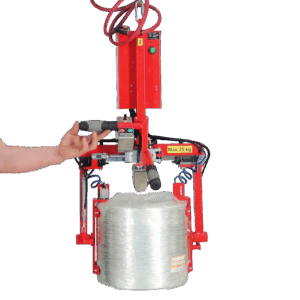

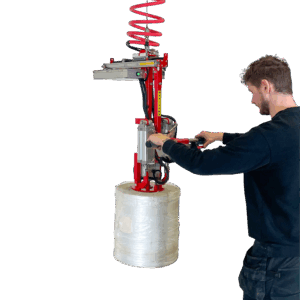

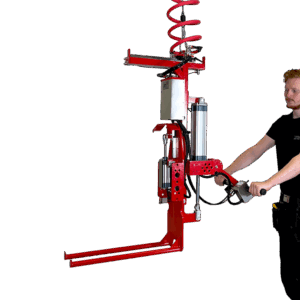

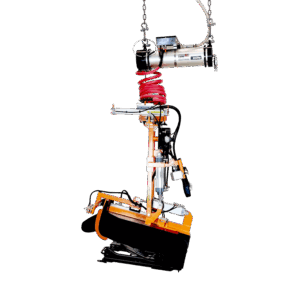

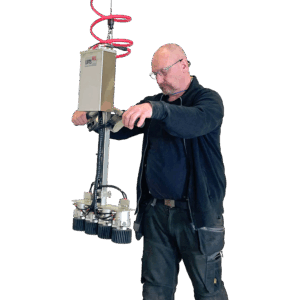

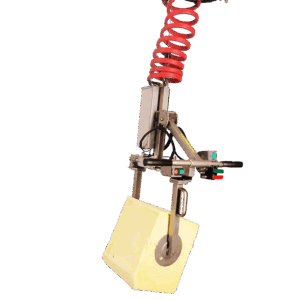

The Lifts All Vacuum Sack Gripper provides safe, efficient handling for airtight paper and plastic sacks up to 50 kg. Designed for ergonomic operation, it offers proportional or balancer control and consumes just 5–10% of the energy used by standard vacuum lifters.

Price on request

Description

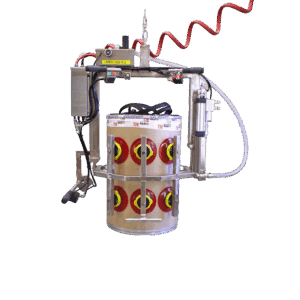

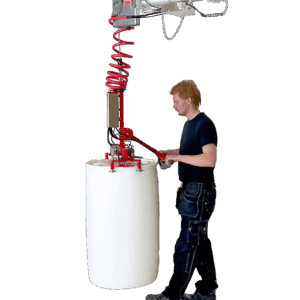

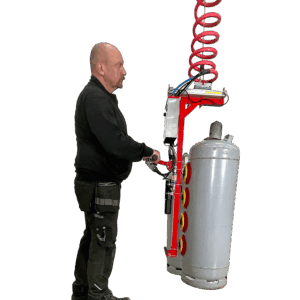

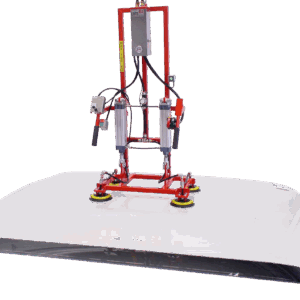

The Lifts All Vacuum Sack Gripper for Paper and Plastic Sacks is a high-performance vacuum lifting and handling tool designed for rapid, ergonomic lifting of airtight sacks and bags weighing up to 50 kg. Perfect for logistics, food processing, packaging, and cleanroom applications, this pneumatic-powered gripper ensures speed, efficiency, and safety in every lift.

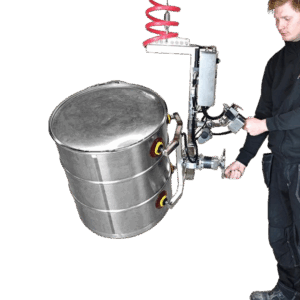

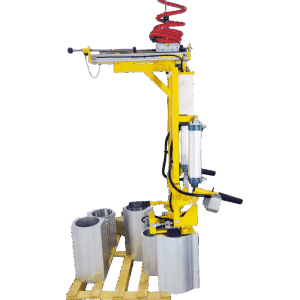

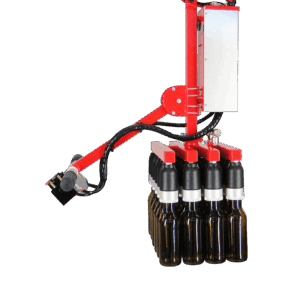

Engineered for airtight sacks such as paper or plastic bags, the Vacuum Sack Gripper enables operators to lift loads directly from pallets to conveyor belts effortlessly. For porous sacks like gunny or laundry bags, we recommend the Lifts All Mechanical Sack Gripper.

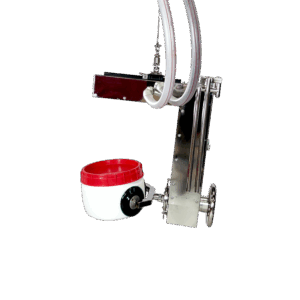

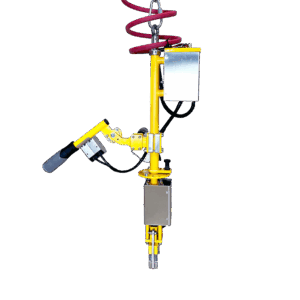

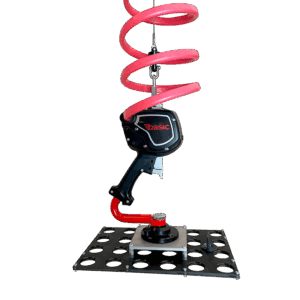

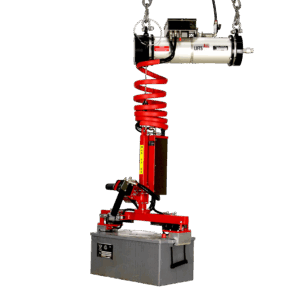

This energy-efficient system uses only 5–10% of the energy consumed by conventional vacuum lifting equipment, thanks to Lifts All’s innovative Precivac pump, which maintains optimal vacuum pressure throughout the lifting process. The result is a quiet, cost-effective, and environmentally friendly solution that improves workflow while reducing operational costs.

Lifting is quick and intuitive, simply place the gripper on the sack, press the green button to activate the vacuum and lift. The sack is secured in just two seconds, allowing for a faster, smoother production rhythm.

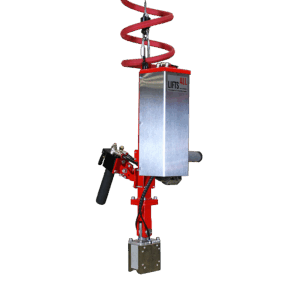

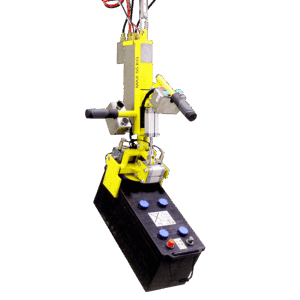

You can choose between two control options:

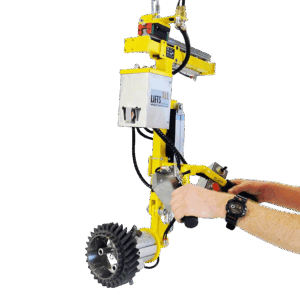

Proportional Speed Control (PSH): Use up/down levers or triggers for precise speed management.

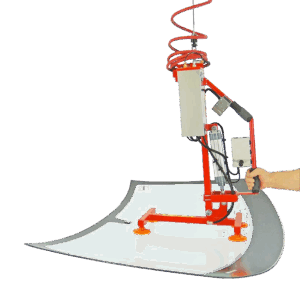

Balancer Control: Move the gripper manually in all directions with your hands for seamless and intuitive manoeuvring.

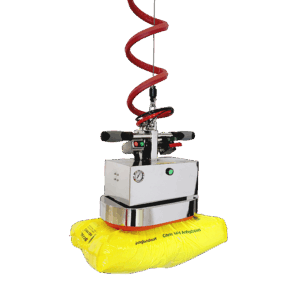

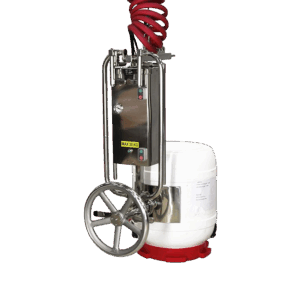

For industries with strict hygiene standards, a stainless-steel version of the Vacuum Sack Gripper is available. This model is easy to clean and designed to prevent particle accumulation, making it ideal for food, pharmaceutical, and cleanroom environments.